Industrial manufacturing

Our integrated know-how

Warping

Integrated preparation of materials

Our sectional and direct warping machines allow us to quickly adapt to demand.

As technology, trends, and sustainability evolve, traditional fibers such as cotton or natural rubber have gradually been replaced by polyamides, microfiber polyamides, Airtex, polyester, microfiber polypropylene, and elastane.

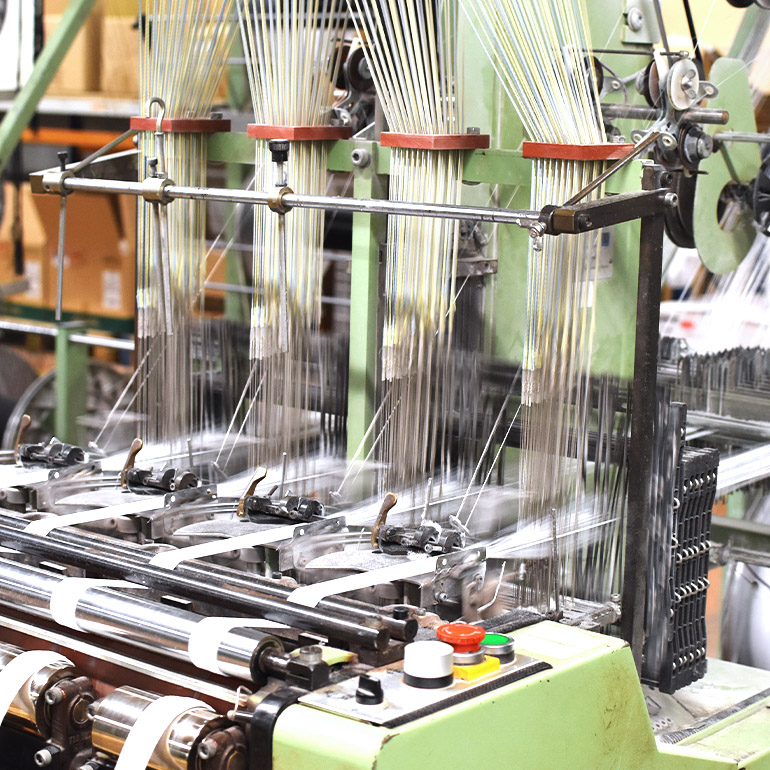

Weaving

Warp and weft

With 90 years of experience and a fleet of more than 100 trades, Berthéas offers a flexible and complete industrial capacity to produce many types of fabrics and elastic ribbons.

Depending on the function of the requested items, we can deliver products widths ranging from 15 to 320 mm.

Feel free to contact us to discover our full ranges in particular through our 3d article structures, hook-and-loop, pocket openwork or bi-elastic.

Finishing

Primers, dyes and special finishing

We offer a wide range of finishing tools for our tapes.

For all unbleached woven ribbons, many dyeing modes are possible depending on price constraints, the desired colors and shades.

We provide a full range of coatings to give your textiles softness, durability, and protection according to your needs.

High customization is possible till the end of the process by embossing of custom pattern or by laser engraving.

Partner network

Nous travaillons avec un réseau réactif de partenaires locaux pour proposer des produits semi-finis ou complets. Ce réseau permet d’intégrer des finitions complémentaires au tissage de nos rubans telles que découpe, couture, soudure, impression ou encore ajout de composants.

Continuous improvement

Bertheas implements an operational excellence approach aimed at continuously improving our products, processes, and working conditions. This is driven by proven methods, standards, active listening, care, and strong team involvement.